Single Color EVA Foam Injection Machine

Single Color EVA Foam Injection Machine

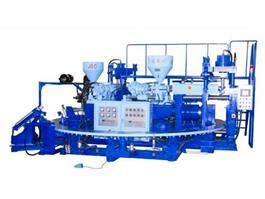

Two Color EVA Shoes Injection Machine

Two Color EVA Shoes Injection Machine

Two Color Rotary PVC Boot Making Machine

Two Color Rotary PVC Boot Making Machine

Single Color Rotary PVC Boot Injection Machine

Single Color Rotary PVC Boot Injection Machine

Rotary PVC Children Boot Making Machine

Rotary PVC Children Boot Making Machine

PVC Blowing Shoes Injection Machine

PVC Blowing Shoes Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC506B Three Color PVC Flip Flops Strap Injection Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

JIC806 Three Color PVC Flip Flops Strap Making Machine

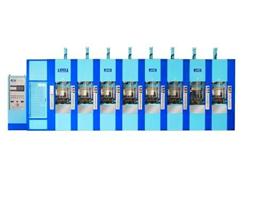

EVA Sole Injection Moulding Machine

EVA Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine

PVC Sole Injection Moulding Machine